NSK-LStandard drillings & slotted hole fixings up to 12.9 strength classes

Areas of application

- Highly stressed and high-strength bolted connections in accordance with VDI 2230-1

- Force-fit, static and dynamic transmission of the operating load via the braced components

- Strength classes 8.8 to 12.9 or A70 and A80

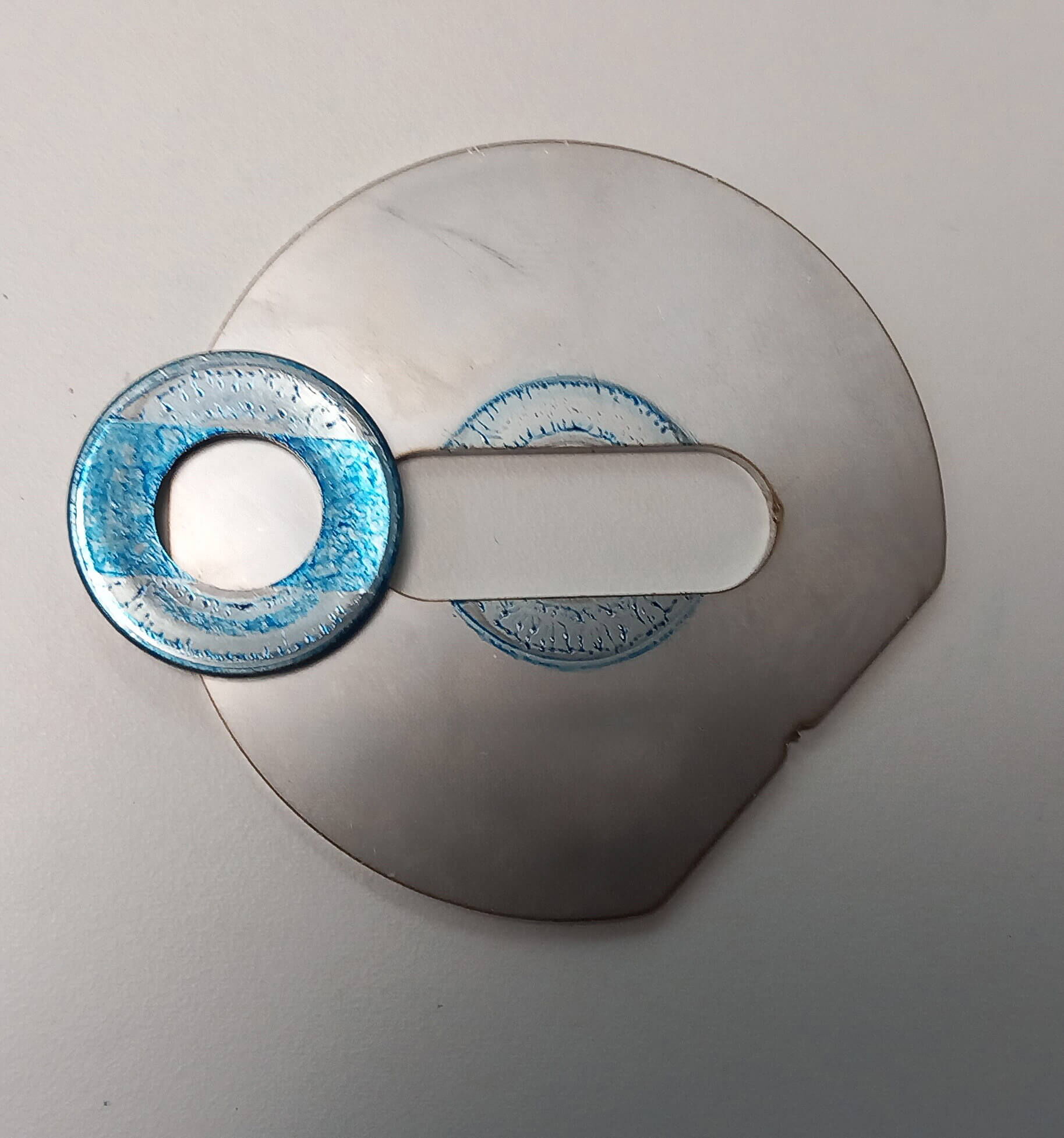

- Circular hole and slotted hole connections

- Effective even with limited installation space (See also NSK-B for larger installation spaces)

Special features

- Suitable for high preload forces

- Defined, Defined, constant friction coefficient

- Increases the flexibility of the screw connection

- Special spring characteristics / optimum residual spring behaviour for strength classes 10.9 and 12.9 (Characteristic spring curves shown in M-Design)

- Locking element to prevent loosening & automatic unscrewing

- Complies with standards DIN 267-26, DIN 25201-4, DIN EN 17976

Comparison of possible solutions for highly stressed and high-strength screw connections

| Spring/profile Locking edge ring1 Spring washer2 with washer |

Wedge disc pairs (flat design) |

Wedge disc pairs (conical design) |

Clamping disc (DIN6796) |

NSK-L | |

|---|---|---|---|---|---|

| Damage to the counterclaims |

|

|

|

|

|

| Defined / reproducible contact pressure (coefficient of friction) |

|

|

|

|

|

| Improved compliance with short clamping lengths |

|

|

|

|

|

| Compensation of slackening effects3 |

|

|

|

|

|

| Compensation of loosening effects4 |

|

|

|

|

|

| Acquisition costs compared to washer DIN 1255 |

|

|

|

|

|

Technical Information

| Spring steel C60 EN 1.1211 |

Stainless steel A41 EN 1.4401 (in preparation) |

Other materials EN 1.4547, EN 2.4819, EN 2.4668 (on request) | |

|---|---|---|---|

| Hardness / Strength | ≥ 430 HV10 | ≥ 595 N/mm2 | depending on material |

| Coating | Zinc flake coating | - | - |

| Corrosion protection | > 720h in the salt spray test (according to ISO 9227) | PREN 27 (bezogen auf Grundwerkstoff) | depending on material |

| Temperature range | -40°C to 150°C | -40°C to 150°C | depending on material |

| Screw quality | 8.8 - 12.9 | up to and including A4-80 |

depending on material |

| Dimension range | M6 - M20 | M6 - M20 | as required |

Applications

Why do screw connections come loose?

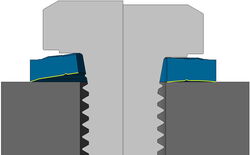

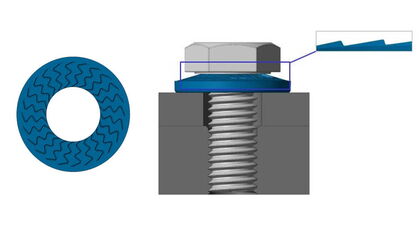

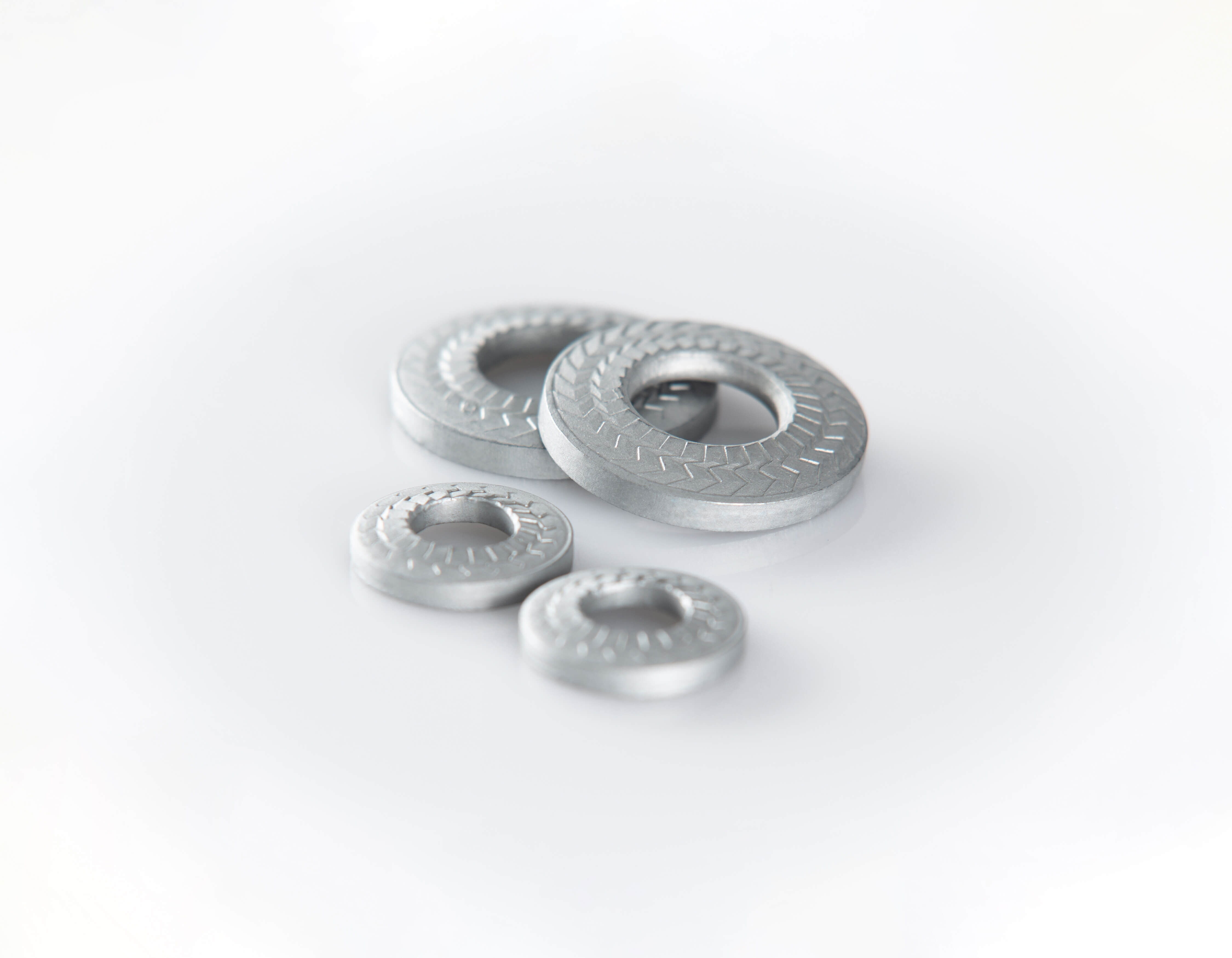

How does an NSK-L work?

Force-locking effect with curved geometry matched to the preload force depending on the strength class.

- Increases the flexibility of a bolted joint

- Prevents slackening effects and supports the locking effect against selfacting loosening

Form locking effect due to the interlocking under the screw head or on the nut.

- Supports the locking effect against selfacting loosening

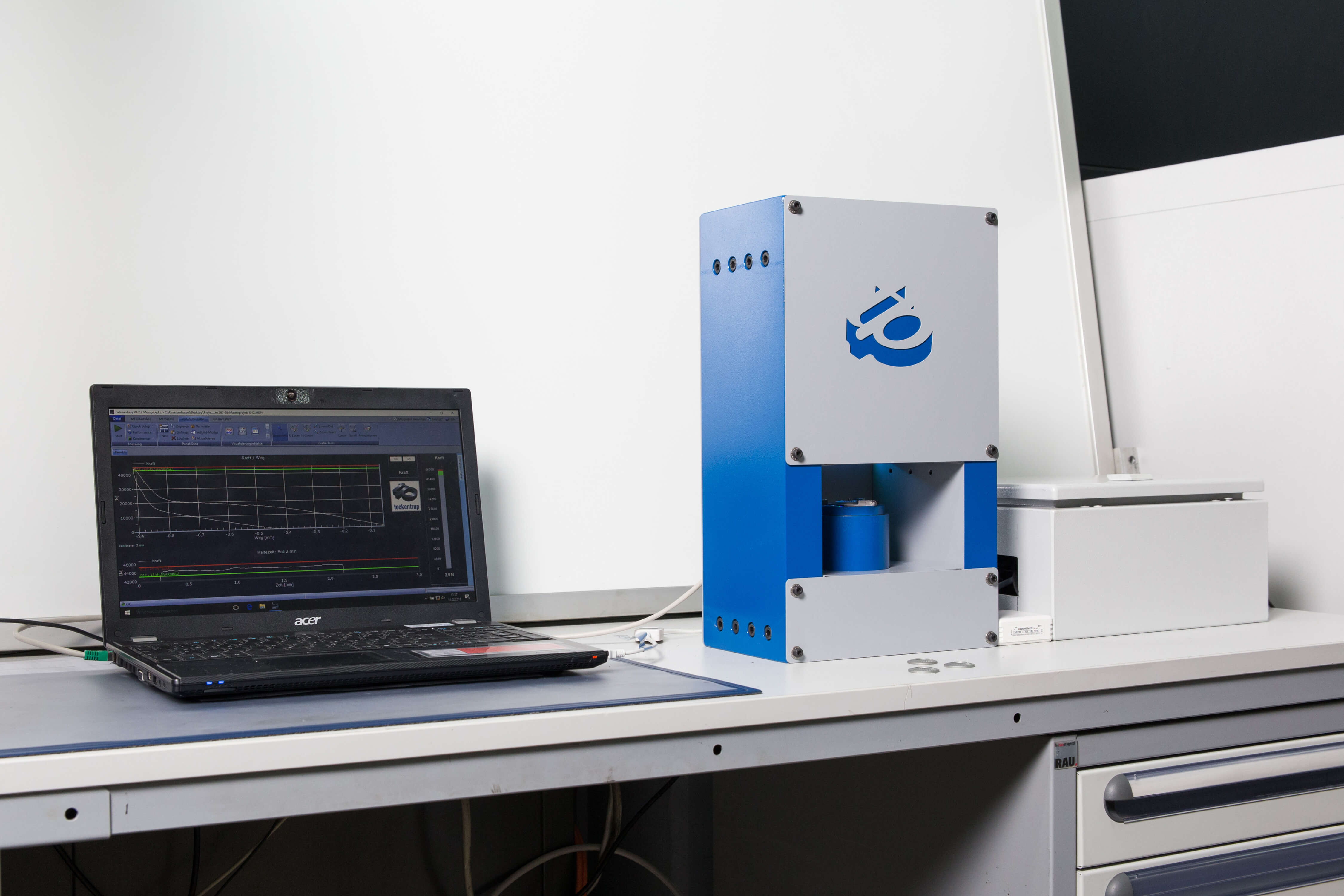

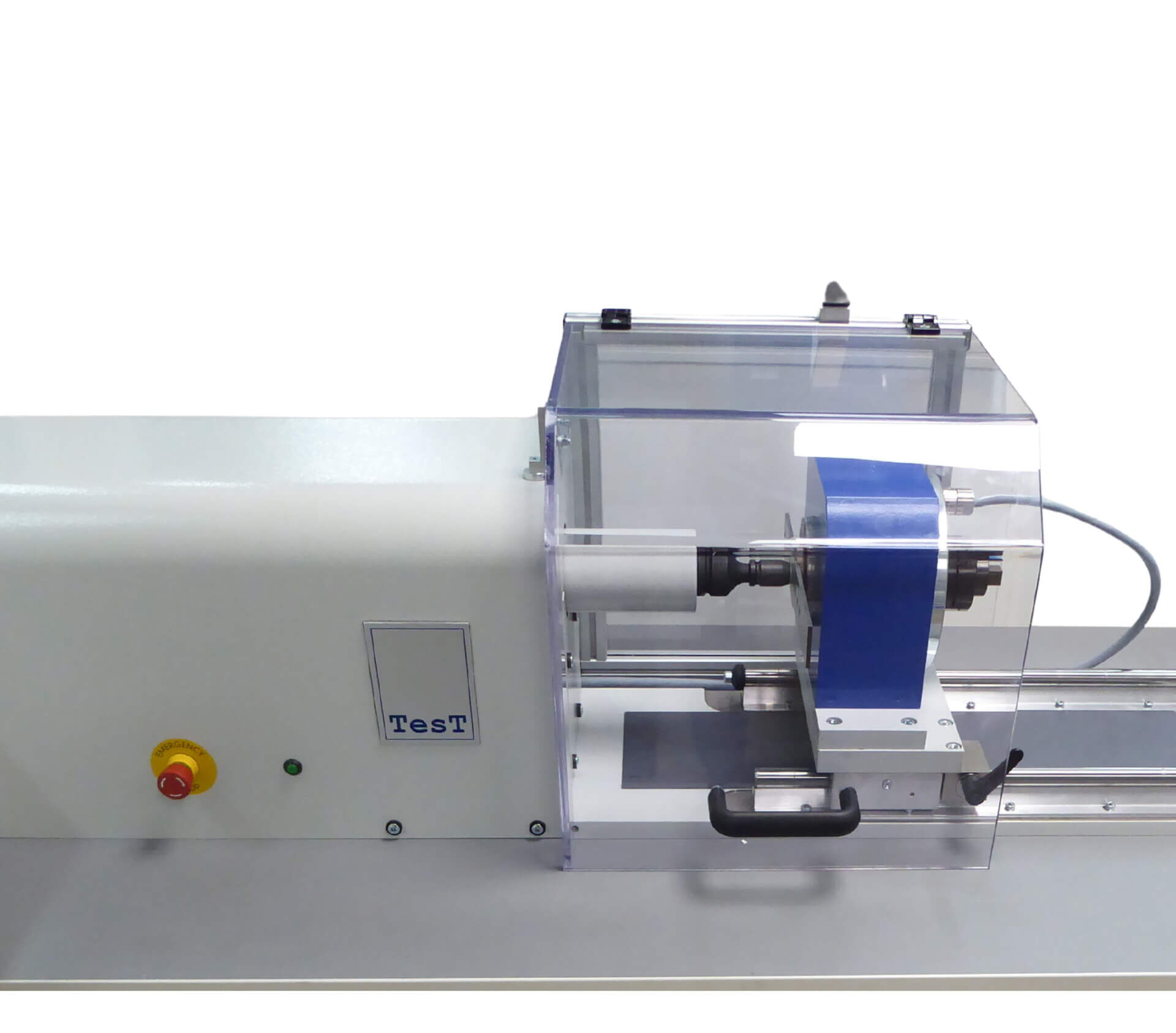

How are NSK-L tested?

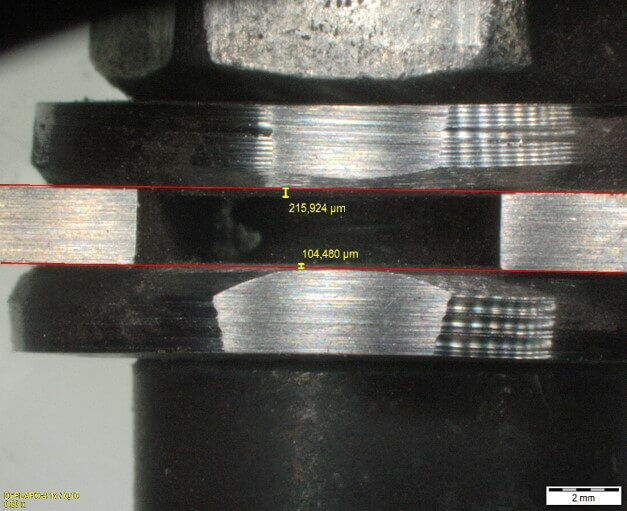

Minimum residual spring force test according to DIN 267-26

Force measurement, if the screw connection is relieved by 20μm (Technical specifications for conical spring steel washers for bolted joints)

Friction coefficients are determined in accordance with DIN 16047

The decisive factors for a constant and defined coefficient of friction with low tolerance are:

a.) the form of the connecting element

b.) the surface coating of the connecting element

Vibration test according to DIN 65151 & DIN 25201-4 Annex B.

- Application-orientated testing on circular-holes and slotted holes

- Internal testing equipment are verified by external institutes.

The functional properties and tests for slotted hole connections are not defined in standards. The tests, carried out by teckentrup SLI, are used for orientation.

The properties and testing methode for slotted hole connections must be specified by the user.

Spring steel (C60) with zinc flake

| NSK-L | Article No. | DI | DA | S | H | Weight/1.000 St. | Pcs. per unit | 3D Download | Request |

|---|---|---|---|---|---|---|---|---|---|

| NSK-L6 | 070230 | Ø 6.10+0,48 | Ø 14.20-0,43 | 2.40±0.04 | 3.10±0.20 | 2,13 kg | 1.000 | Download | Add to request list |

| NSK-L8 | 070240 | Ø 8.20+0.58 | Ø 18.20-0.52 | 2.40±0.05 | 3.40±0.25 | 3,94 kg | 1.000 | Download | Add to request list |

| NSK-L10 | 070250 | Ø 10.20+0.58 | Ø 22.25-0.52 | 2.80±0.06 | 3.70±0.25 | 6,83 kg | 500 | Download | Add to request list |

| NSK-L12 | 070260 | Ø 12.40+0.58 | Ø 27.25-0.52 | 2.80±0.06 | 4.30±0.25 | 10,11 kg | 500 | Download | Add to request list |

| NSK-L14 | 070270 | Ø 14.40+0.58 | Ø 30.25-0,52 | 3.50±0.06 | 4.70±0.25 | 15,27 kg | 250 | Download | Add to request list |

| NSK-L16 | 070280 | Ø 16.40+0.58 | Ø 32.50-0.52 | 3.50±0.07 | 4.90±0.30 | 16,80 kg | 250 | Download | Add to request list |

| NSK-L20 | 070300 | Ø 21,00+0,58 | Ø 40,00-0,52 | 4.00±0.07 | 6.00±0.30 | 28,58 kg | 100 | Download | Add to request list |

3D Download

We are happy to provide you with the design files of our discs as STP data. Please enter the information below to download the file.