NSK-KElectrically conductive connections

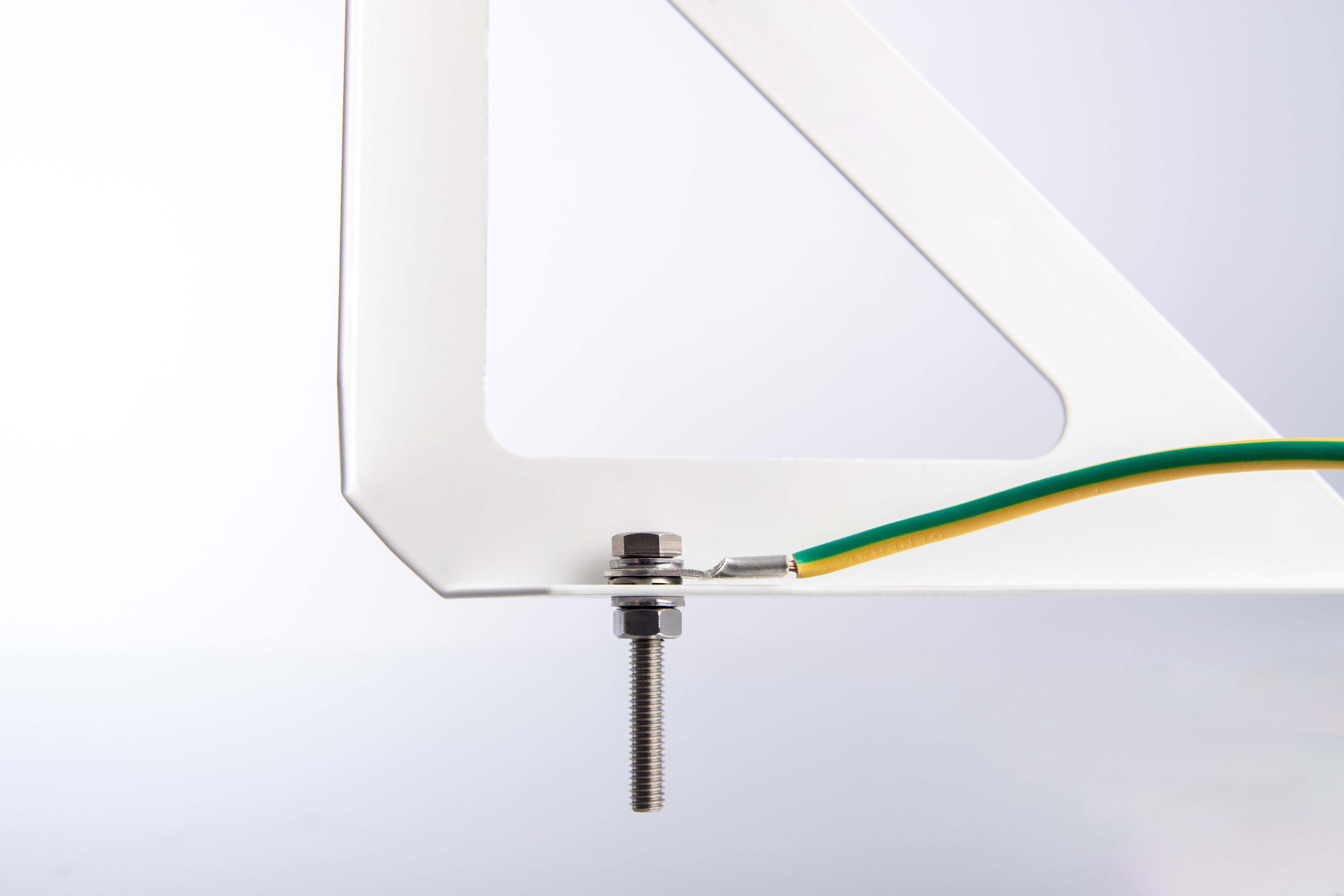

Areas of application

- Establishing an electrically conductive screw connection between conductive parts in order to achieve potential equalisation between components (Potential equalisation is often colloquially referred to as earthing).

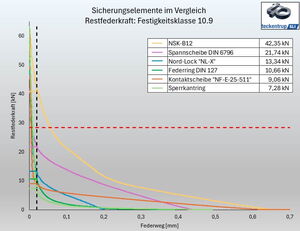

- Functional reliability thanks to optimised residual spring properties to prevent slackening and loosening effects

Special features

- Suitable for application-specific, low preload forces

- Defined, constant coefficient of friction

- Increases the flexibility of the screw connection

- Locking element to prevent loosening & automatic unscrewing

- Standard-compliant according to SN 70093

Comparison of possible solutions for electrical connections (equipotentiality)

| Spring/profile Locking edge ring1 Spring washer2 with washer |

Contact disc (other manufacturers) |

Clamping disc (DIN6796) |

Lock washer SK-K |

NSK-K | |

|---|---|---|---|---|---|

| Uniform contact pressure |

|

|

|

|

|

| Defined / reproducible preload force (coefficient of friction) |

|

|

|

|

|

| Compensation of slackening effects3 |

|

|

|

|

|

| Installation effort and risk |

|

|

|

|

|

| Promotes electrical conductivity |

|

|

|

|

|

| One-piece threadlocking solution4 |

|

|

|

|

|

| Dimensions comply with SN 70026 |

|

|

|

|

|

| Acquisition costs compared to washer DIN 1255 |

|

|

|

|

|

1

DIN 127, 128, 6905, 7980 ec.

2

DIN 137, 6904

3

based on VDI 2230, DIN 267-26

4

in accordance with DIN EN 17976

5

same / higher / high

Technical information

| Spring steel C60 EN 1.1211 |

Stainless steel A41 EN 1.4401 |

Other materials EN 1.4547, EN 2.4819, EN 2.4668 (on request) | |

|---|---|---|---|

| Hardness / Strength | ≥ 430 HV10 | ≥ 595 N/mm2 | depending on material |

| Coating | Zinc flake coating | - | - |

| Corrosion protection | Min. 720h in the salt spray test (according to ISO 9227) |

PREN 27 | depending on material |

| Temperature range | -40°C to 150°C | -40°C to 150°C | depending on material |

| Screw quality | max. 8.8 | up to and including A4-80 |

depending on material |

| Dimension range | M4 - M12 | M4 -M12 | as required |

1

can also be used for stainless steel A2 screws, e.g. EN 1.4301 or EN 1.4310

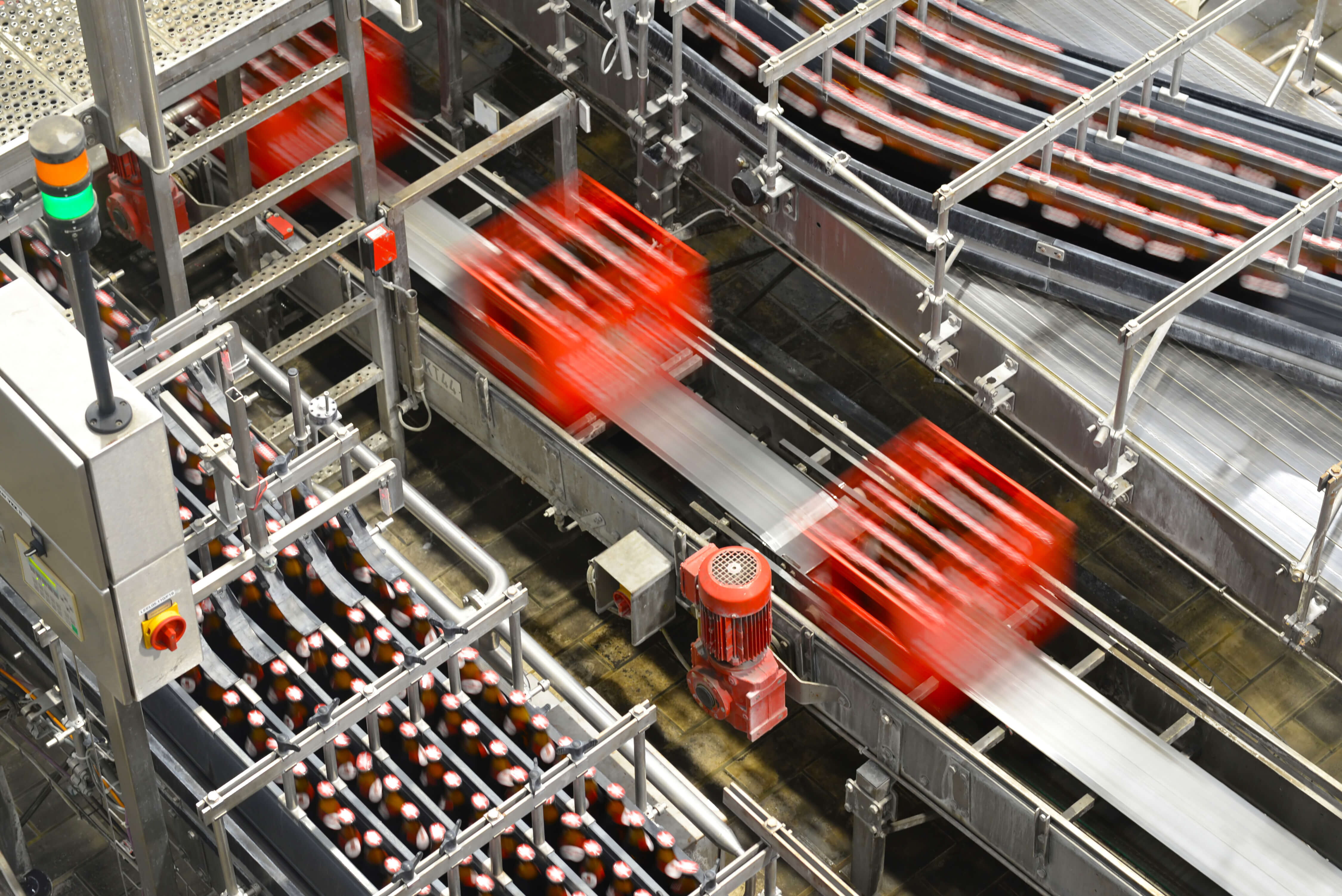

Applications

How does equipotential bonding work?

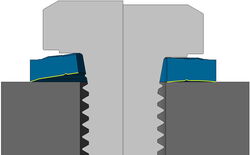

Why do screw connections come loose?

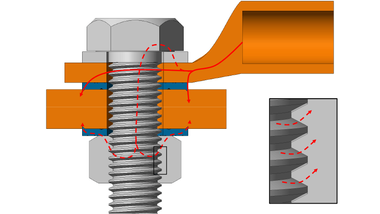

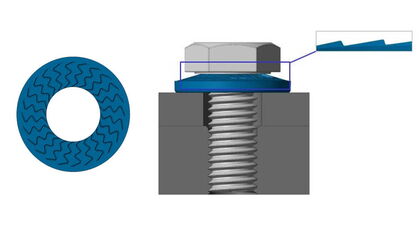

How does an NSK-K work?

Force-locking effect with curved geometry matched to the preload force depending on the strength class

- Increases the flexibility of a bolted joint

- Prevents slackening effects and supports the locking effect against selfacting loosening

Form locking effect due to the interlocking under the screw head or on the nut

- Supports the locking effect against selfacting loosening

Spring characteristic curve, matched to:

- ≤ 8.8 Strength class (steel)

- A70 / A80 for stainless steel 1.4401

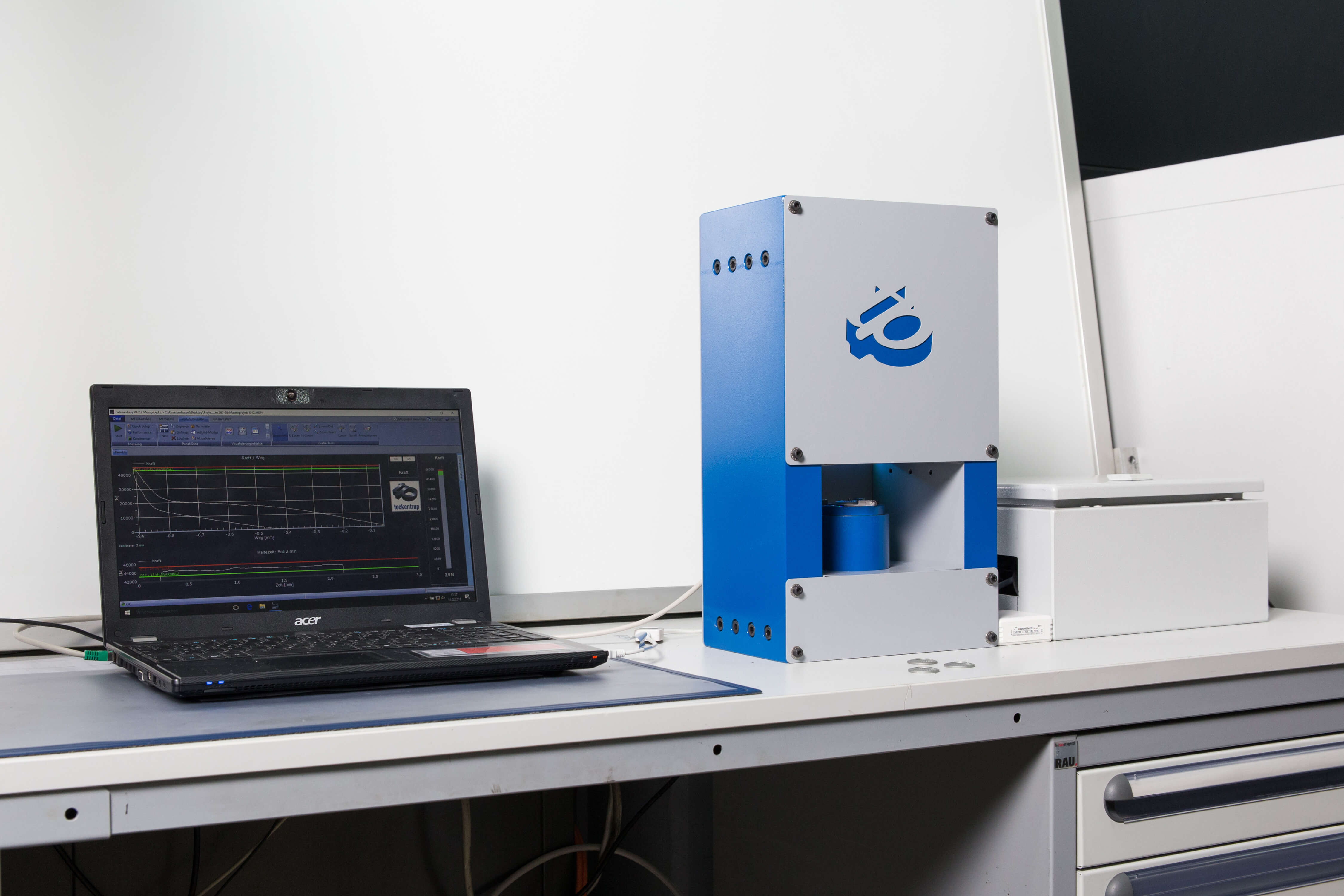

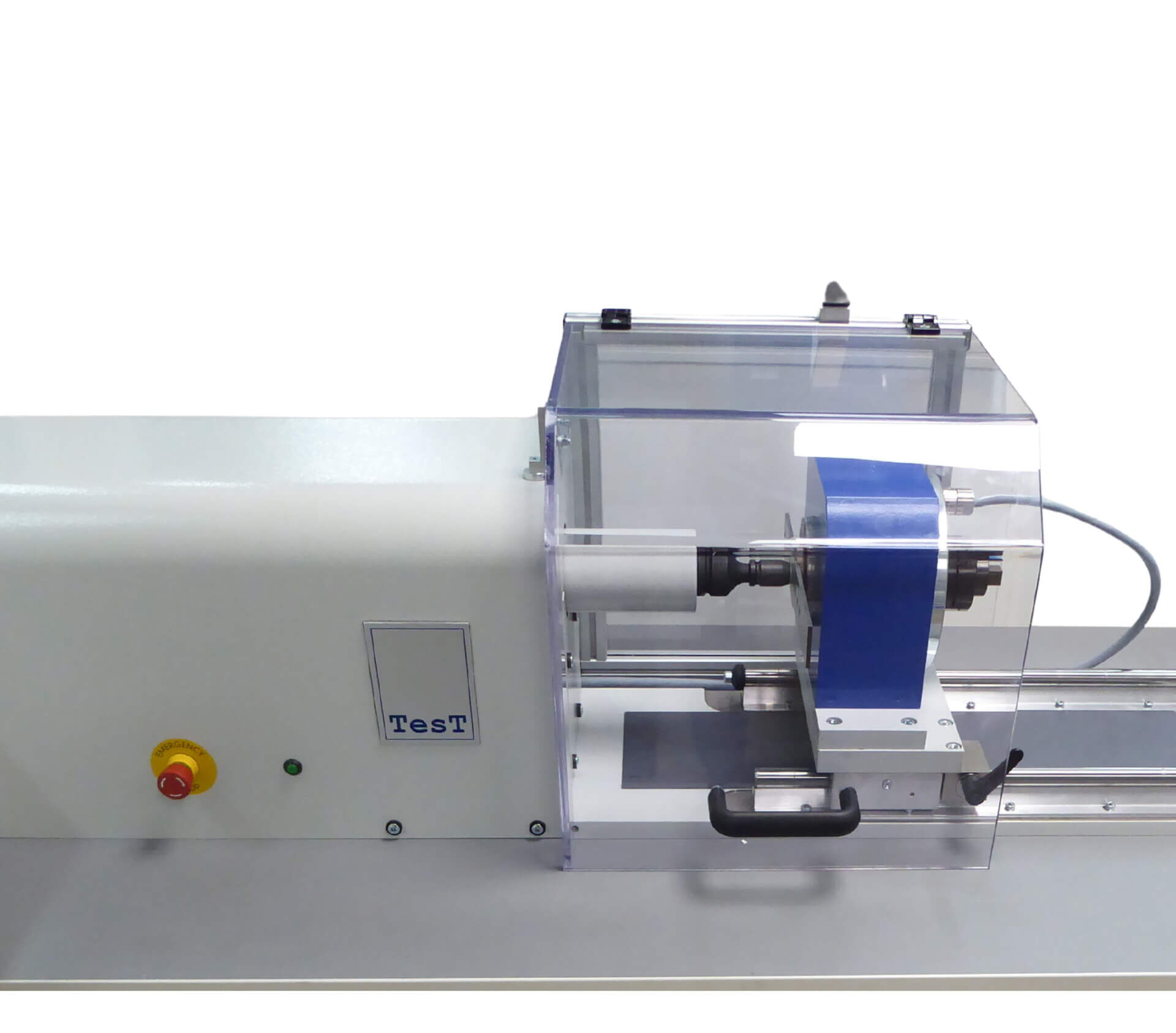

How are NSK-K tested?

Friction coefficients are determined in accordance with DIN 16047

The decisive factors for a constant and defined coefficient of friction with low tolerance are

a.) the form of the connecting element

b.) the surface coating of the connecting element

Spring steel (C60) with zinc flake

| NSK-K | Article No. | DI | DA | S | H | Width tooth m |

Height tooth n |

Weight/1.000 St. | Pcs. per unit | 3D Download | Request |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NSK-K4 | 070710 | Ø 4.10+0.48 | Ø 8.20-0.40 | 1.00±0.03 | 1.30±0.20 | 1.20±0.10 | 0.20+0.20/-0.10 | 0,30 kg | 1.000 | Download | Add to request list |

| NSK-K5 | 070720 | Ø 5.10+0.48 | Ø 10.20-0.40 | 1.00±0.03 | 1.50±0.20 | 2.00±0.10 | 0.40+0.30/-0.10 | 0,43 kg | 1.000 | Download | Add to request list |

| NSK-K6 | 070730 | Ø 6.10+0.48 | Ø 12.20-0.40 | 1.20±0.04 | 1.90±0.20 | 2.00±0.20 | 0.40+0.30/-0.10 | 0,80 kg | 1.000 | Download | Add to request list |

| NSK-K8 | 070740 | Ø 8.20+0.58 | Ø 16.20-0.50 | 1.40±0.04 | 2.40±0.25 | 2.00±0.20 | 0.40+0.30/-0.10 | 1,60 kg | 1.000 | Download | Add to request list |

| NSK-K10 | 070750 | Ø 10.20+0.58 | Ø 20.25-0.50 | 1.60±0.04 | 2.75±0.25 | 2.00±0.20 | 0.40+0.30/-0.10 | 2,80 kg | 500 | Download | Add to request list |

| NSK-K12 | 070760 | Ø 12.40+0.58 | Ø 24.25-0.50 | 1.60±0.04 | 3.00±0.25 | 2.00±0.20 | 0.40+0.30/-0.10 | 4,00 kg | 500 | Download | Add to request list |

| NSK-K16 | 070780 | Ø 16.40+0.58 | Ø 32.30-0.62 | 2.50±0.06 | 5,00±0.30 | 4.00±0.20 | 0.40+0.30/-0.10 | 12,00 kg | 250 | Download | Add to request list |

Stainless steel A4 / 1.4401

| NSK-K | Article No. | DI | DA | S | H | Width tooth m |

Height tooth n |

Weight/1.000 St. | Pcs. per unit | 3D Download | Request |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NSK-K4 | 076710 | Ø 4.10+0.48 | Ø 8.20-0.40 | 1.00±0.03 | 1.30±0.20 | 1.20±0.10 | 0.20+0.20/-0.10 | 0,30 kg | 1.000 | Download | Add to request list |

| NSK-K5 | 076720 | Ø 5.10+0.48 | Ø 10.20-0.40 | 1.00±0.03 | 1.50±0.20 | 2.00±0.10 | 0.40+0.30/-0.10 | 0,43 kg | 1.000 | Download | Add to request list |

| NSK-K6 | 076730 | Ø 6.10+0.48 | Ø 12.20-0.40 | 1.20±0.04 | 1.90±0.20 | 2.00±0.20 | 0.40+0.30/-0.10 | 0,80 kg | 1.000 | Download | Add to request list |

| NSK-K8 | 076740 | Ø 8.20+0.58 | Ø 16.20-0.50 | 1.40±0.04 | 2.40±0.25 | 2.00±0.20 | 0.40+0.30/-0.10 | 1,60 kg | 1.000 | Download | Add to request list |

| NSK-K10 | 076750 | Ø 10.20+0.58 | Ø 20.25-0.50 | 1.60±0.04 | 2.75±0.25 | 2.00±0.20 | 0.40+0.30/-0.10 | 2,80 kg | 500 | Download | Add to request list |

| NSK-K12 | 076760 | Ø 12.40+0.58 | Ø 24.25-0.50 | 1.60±0.04 | 3.00±0.25 | 2.00±0.20 | 0.40+0.30/-0.10 | 4,00 kg | 500 | Download | Add to request list |

| NSK-K16 | 076780 | Ø 16.40+0.58 | Ø 32.30-0.62 | 2.50±0.06 | 5,00±0.30 | 4.00±0.20 | 0.40+0.30/-0.10 | 12,00 kg | 250 | Download | Add to request list |

Technical changes reserved

Contact washers are used for establishing electroconductive connections (eg for earth and ground connections) of coated equipment parts with coating thicknesses of up to 100μm. See also SN 70093.

Contact washers are used for establishing electroconductive connections (eg for earth and ground connections) of coated equipment parts with coating thicknesses of up to 100μm. See also SN 70093.

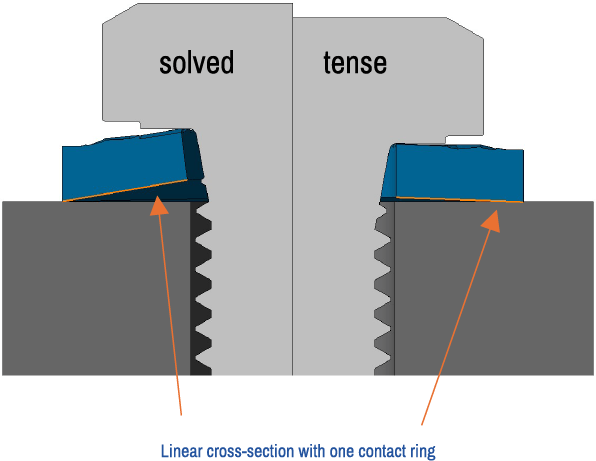

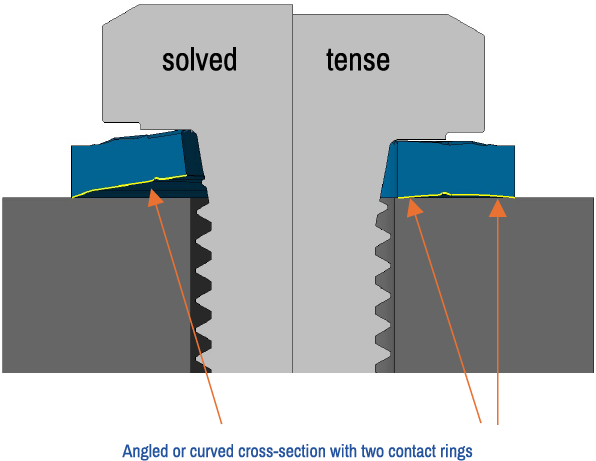

What is the difference between SK and NSK washers?

| Lock washer (SK Washer) |

New lock washer (NSK washer) |

|

|---|---|---|

| State of development |

1990

|

2007 cont.

|

| Form |

Linear cross- section

|

Angled or curved cross-section with bead

|

| Compensation of loosening effects1 |

|

|

| Compensation of loosening effects2 |

|

|

| Fulfilment of the teckentrup product characteristics |

|

|

| Costs |

|

|

1

according to DIN 65151 and, if applicable, DIN 25201 - 4 2021-11, depending on design with adapted parameters depending on strength class etc.

2

based on VDI 2230, DIN 267-26 2005-12

The SK washers are produced by different manufacturers worldwide and may have different functional properties with the same external appearance.

SK washer

NSK washer

SK-K for electroconductive connections

Spring steel with zinc flake

| SK-K | Article No. | DI | DA | S | H | Width tooth m |

Height tooth n |

Weight/1.000 St. | Pcs. per unit | Request |

|---|---|---|---|---|---|---|---|---|---|---|

| SK-K4 | 090710 | Ø 4.10+0.48 | Ø 8.20-0.40 | 1.00±0.03 | 1.35-0.15 | 1.20±0.10 | 0.20+0.20/-0.10 | 0,30 kg | 1.000 | Add to request list |

| SK-K5 | 090720 | Ø 5.10+0.48 | Ø 10.20-0.40 | 1.00±0.03 | 1.50-0.25 | 2.00±0.10 | 0.40+0.30/-0.10 | 0,43 kg | 1.000 | Add to request list |

| SK-K6 | 090730 | Ø 6.10+0.48 | Ø 12.20-0.40 | 1.20±0.04 | 1.80-0.30 | 2.00±0.20 | 0.40+0.30/-0.10 | 0,80 kg | 1.000 | Add to request list |

| SK-K8 | 090740 | Ø 8.20+0.58 | Ø 16.20-0.50 | 1.40±0.04 | 2.40-0.45 | 2.00±0.20 | 0.40+0.30/-0.10 | 1,60 kg | 1.000 | Add to request list |

| SK-K10 | 090750 | Ø 10.20+0.58 | Ø 20.25-0.50 | 1.60±0.04 | 2.60-0.45 | 2.00±0.20 | 0.40+0.30/-0.10 | 2,80 kg | 500 | Add to request list |

| SK-K12 | 090760 | Ø 12.40+0.58 | Ø 24.25-0.50 | 1.60±0.04 | 2.60-0.45 | 2.00±0.20 | 0.40+0.30/-0.10 | 4,00 kg | 500 | Add to request list |

Stainless steel A4 / 1.4401

| SK-K | Article No. | DI | DA | S | H | Width tooth m |

Height tooth n |

Weight/1.000 St. | Pcs. per unit | Request |

|---|---|---|---|---|---|---|---|---|---|---|

| SK-K4 | 096710 | Ø 4.10+0.48 | Ø 8.20-0.40 | 1.00±0.03 | 1.35-0.15 | 1.20±0.10 | 0.20+0.20/-0.10 | 0,30 kg | 1.000 | Add to request list |

| SK-K5 | 096720 | Ø 5.10+0.48 | Ø 10.20-0.40 | 1.00±0.03 | 1.50-0.25 | 2.00±0.10 | 0.40+0.30/-0.10 | 0,43 kg | 1.000 | Add to request list |

| SK-K6 | 096730 | Ø 6.10+0.48 | Ø 12.20-0.40 | 1.20±0.04 | 1.80-0.30 | 2.00±0.20 | 0.40+0.30/-0.10 | 0,80 kg | 1.000 | Add to request list |

| SK-K8 | 096740 | Ø 8.20+0.58 | Ø 16.20-0.50 | 1.40±0.04 | 2.40-0.45 | 2.00±0.20 | 0.40+0.30/-0.10 | 1,60 kg | 1.000 | Add to request list |

| SK-K10 | 096750 | Ø 10.20+0.58 | Ø 20.25-0.50 | 1.60±0.04 | 2.60-0.45 | 2.00±0.20 | 0.40+0.30/-0.10 | 2,80 kg | 500 | Add to request list |

| SK-K12 | 096760 | Ø 12.40+0.58 | Ø 24.25-0.50 | 1.60±0.04 | 2.60-0.45 | 2.00±0.20 | 0.40+0.30/-0.10 | 4,00 kg | 500 | Add to request list |

Technical changes reserved

Contact washers are used for establishing electroconductive connections (eg for earth and ground connections) of coated equipment parts with coating thicknesses of up to 100μm. See also SN 70093.

3D Download

We are happy to provide you with the design files of our discs as STP data. Please enter the information below to download the file.