NSK-BSlotted hole fixings up to 12.9 strength classes

Areas of application

- Highly stressed and high-strength bolted connections in accordance with VDI 2230-

- Force-fit, static and dynamic transmission of the operating load via the braced components

- Strength classes up to 12.9 or A80

- Circular hole and slotted hole connections (See also NSK-L for small installation spaces)

Special features

- Suitable for high preload forces

- Defined, constant coefficient of friction

- Increases the flexibility of the screw connection

- Special spring characteristics / optimum residual spring behaviour for strength classes 10.9 and 12.9 (Spring characteristics stored e.g. at M-Design)

- Locking element to prevent loosening & automatic unscrewing

- Complies with standards DIN 267-26, DIN 25201-4, DIN EN 17976

Comparison of possible solutions for highly stressed and high-strength bolted joints

| Spring/profile Locking edge ring1 Spring washer2 with washer |

Wedge disc pairs (flat design) |

Wedge disc pairs (conical design) |

Clamping disc (DIN6796) |

Locking washer SK-B | NSK-B | |

|---|---|---|---|---|---|---|

| Damage to the counterclaims |

|

|

|

|

|

|

| Defined / reproducible contact pressure (coefficient of friction) |

|

|

|

|

|

|

| Improved compliance with short clamping lengths |

|

|

|

|

|

|

| Compensation of slackening effects3 |

|

|

|

|

|

|

| Compensation of loosening effects4 |

|

|

|

|

|

|

| Acquisition costs compared to washer DIN 1255 |

|

|

|

|

|

|

1

DIN 127, 128, 6905, 7980 etc.

2

DIN 137, 6904

3

according to VDI 2230, DIN 267-26

4

in accordance with DIN 65151 / DIN 25201-4

5

same / higher / high

Technical information

| Spring steel C60 EN 1.1211 |

Stainless steel A41 EN 1.4401 |

Other materials EN 1.4547, EN 2.4819, EN 2.4668 (on request) | |

|---|---|---|---|

| Hardness / Strength | ≥ 430 HV10 | ≥ 595 N/mm2 | depending on material |

| Coating | Zinc flake coating | - | - |

| Corrosion protection | > 720h in the salt spray test (according to ISO 9227) |

PREN 27 (related to base material) |

depending on material |

| Temperature range | -40°C to 150°C | -40°C to 150°C | depending on material |

| Screw quality | 8.8 - 12.9 | up to and including A4-80 |

depending on material |

| Dimension range | M5 - M16 | M5 - M16 | as required |

1

can also be used for stainless steel A2 screws, e.g. EN 1.4301 or EN 1.4310

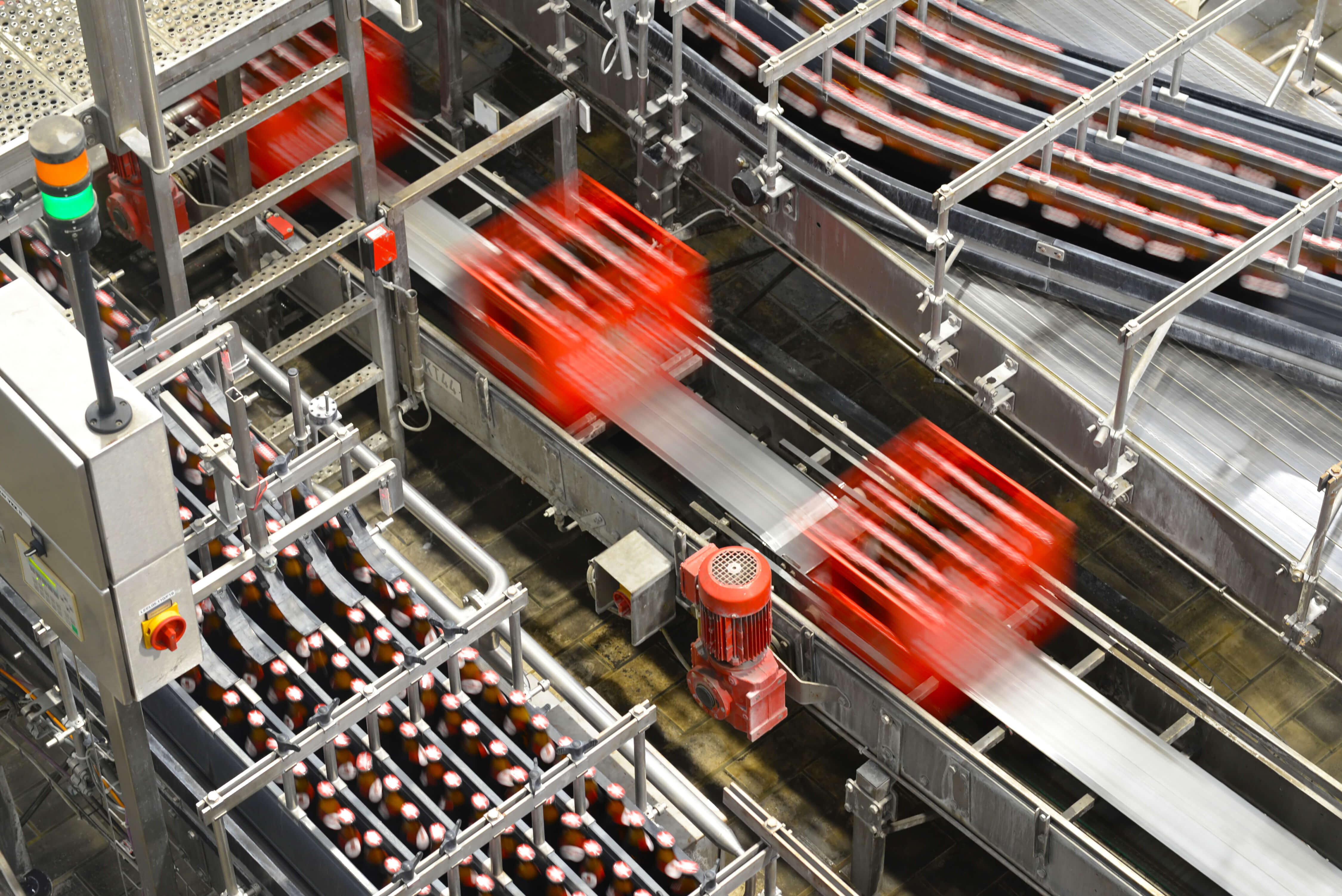

Applications

Why do screw connections come loose?

How does an NSK-B work?

Force-locking effect with curved geometry matched to the preload force depending on the strength class

- Increases the flexibility of a bolted joint

- Prevents slackening effects and supports the locking effect against selfacting loosening

Form locking effect due to the interlocking under the screw head or on the nut

- Supports the locking effect against selfacting loosening

How are NSK-B tested?

Minimum residual spring force test according to DIN 267-26

Force measurement, if the screw connection is relieved by 20μm (Technical specifications for conical spring steel washers for bolted joints)

Spring characteristic curve, matched to:

- Strength class 10.9 and 12.9 (steel)

- A80 for stainless steel 1.4401

Vibration test according to DIN 65151 & DIN 25201-4 Annex B.

- Application-orientated testing on circular-holes and slotted holes

- Internal testing equipment are verified by external institutes.

Spring steel (C60) with zinc flake

| NSK-B | Article No. | DI | DA | S | H | Weight/1.000 St. | Pcs. per unit | 3D Download | Request |

|---|---|---|---|---|---|---|---|---|---|

| NSK-B5 | 070520 | Ø 5.10+0.48 | Ø 18.20-0.52 | 1.40±0.04 | 2.60±0.20 | 2,50 kg | 1.000 | Download | Add to request list |

| NSK-B6 | 070530 | Ø 6.10+0.48 | Ø 18.20-0.52 | 1.40±0.04 | 2.60±0.20 | 2,50 kg | 1.000 | Download | Add to request list |

| NSK-B8 | 070540 | Ø 8.20+0.58 | Ø 22.25-0.52 | 1.90±0.05 | 3.10±0.25 | 5,00 kg | 500 | Download | Add to request list |

| NSK-B10 | 070550 | Ø 10.20+0.58 | Ø 27.25-0.52 | 2.40±0.05 | 3.60±0.25 | 9,40 kg | 500 | Download | Add to request list |

| NSK-B12 | 070560 | Ø 12.40+0.58 | Ø 32.30-0.62 | 2.80±0.06 | 4.80±0.25 | 15,40 kg | 250 | Download | Add to request list |

| NSK-B16 | 070580 | Ø 16.40+0.58 | Ø 45,40-0.62 | 3.50±0.07 | 5.40±0.30 | 38,00 kg | 100 | Download | Add to request list |

Stainless steel A4 / 1.4401

| NSK-B | Article No. | DI | DA | S | H | Weight/1.000 St. | Pcs. per unit | 3D Download | Request |

|---|---|---|---|---|---|---|---|---|---|

| NSK-B5 | 076520 | Ø 5.10+0.48 | Ø 18.20-0.52 | 1.40±0.04 | 2.60±0.20 | 2,50 kg | 1.000 | Download | Add to request list |

| NSK-B6 | 076530 | Ø 6.10+0.48 | Ø 18.20-0.52 | 1.40±0.04 | 2.60±0.20 | 2,50 kg | 1.000 | Download | Add to request list |

| NSK-B8 | 076540 | Ø 8.20+0.58 | Ø 22.25-0.52 | 1.90±0.05 | 3.10±0.25 | 5,00 kg | 500 | Download | Add to request list |

| NSK-B10 | 076550 | Ø 10.20+0.58 | Ø 27.25-0.52 | 2.40±0.05 | 3.60±0.25 | 9,40 kg | 500 | Download | Add to request list |

| NSK-B12 | 076560 | Ø 12.40+0.58 | Ø 32.30-0.62 | 2.80±0.06 | 4.80±0.25 | 15,40 kg | 250 | Download | Add to request list |

| NSK-B16 | 076580 | Ø 16.40+0.58 | Ø 45,40-0.62 | 3.50±0.07 | 5.40±0.30 | 38,00 kg | 100 | Download | Add to request list |

Technical changes reserved

The securing effect of the NSK-B and NSK-L on slotted holes is verified using a wide range of test methods. The hole clearance in the transverse direction corresponds to normal holes (DIN EN 20273; tolerance class H 13, medium). Furthermore, slotted hole edges are always deburred. For your own applications, it is recommended that you carry out your own tests with specialised personnel.

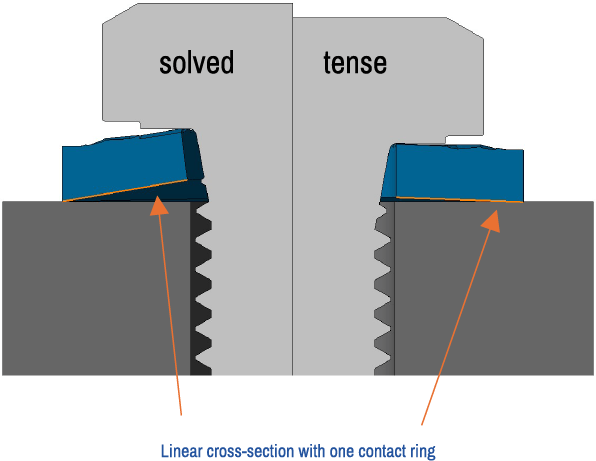

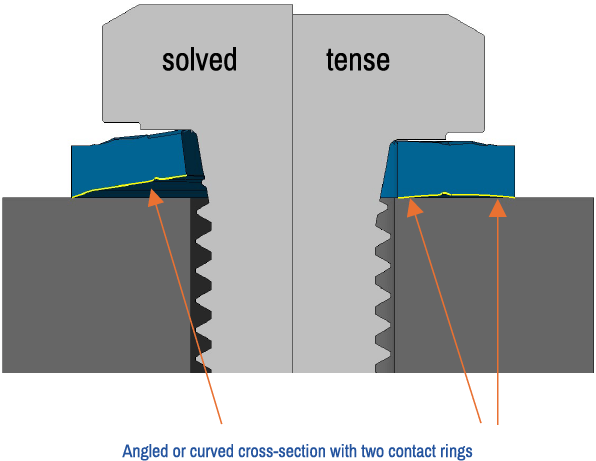

What is the difference between SK and NSK washers?

| Lock washer (SK Washer) |

New lock washer (NSK washer) |

|

|---|---|---|

| State of development |

1990

|

2007 cont.

|

| Form |

Linear cross- section

|

Angled or curved cross-section with bead

|

| Compensation of loosening effects1 |

|

|

| Compensation of loosening effects2 |

|

|

| Fulfilment of the teckentrup product characteristics |

|

|

| Costs |

|

|

1

according to DIN 65151 and, if applicable, DIN 25201 - 4 2021-11, depending on design with adapted parameters depending on strength class etc.

2

based on VDI 2230, DIN 267-26 2005-12

The SK washers are produced by different manufacturers worldwide and may have different functional properties with the same external appearance.

SK washer

NSK washer

SK-B (wide) for large pressure transfer surfaces and slotted hole connections ≤ 12.9

Spring steel with zinc flake

| SK-B | Article No. | DI | DA | S | H | Weight/1.000 St. | Pcs. per unit | Request |

|---|---|---|---|---|---|---|---|---|

| SK-B6 | 090530 | Ø 6.10+0.48 | Ø 18.20-0.52 | 1.40±0.04 | 2.35+0.20 | 2,50 kg | 1.000 | In the request list |

| SK-B8 | 090540 | Ø 8.20+0.58 | Ø 22.25-0.52 | 1.90±0.05 | 2.70+0.20 | 5,00 kg | 500 | In the request list |

| SK-B10 | 090550 | Ø 10.20+0.58 | Ø 27.25-0.52 | 2.40±0.05 | 3.45+0.20 | 9,40 kg | 500 | In the request list |

| SK-B12 | 090560 | Ø 12.40+0.58 | Ø 32.30-0.62 | 2.80±0.06 | 4.30+0.20 | 15,40 kg | 250 | In the request list |

| SK-B16 | 092410 | Ø 16.40+0.58 | Ø 45,40-0.62 | 3.50±0.07 | 5.40+0.50 | 38,00 kg | 100 | In the request list |

Stainless steel A4 / 1.4401

| SK-B | Article No. | DI | DA | S | H | Weight/1.000 St. | Pcs. per unit | Request |

|---|---|---|---|---|---|---|---|---|

| SK-B6 | 096530 | Ø 6.10+0.48 | Ø 18.20-0.52 | 1.40±0.04 | 2.35+0.20 | 2,50 kg | 1.000 | Add to request list |

| SK-B8 | 096540 | Ø 8.20+0.58 | Ø 22.25-0.52 | 1.90±0.05 | 2.70+0.20 | 5,00 kg | 500 | Add to request list |

| SK-B10 | 096550 | Ø 10.20+0.58 | Ø 27.25-0.52 | 2.40±0.05 | 3.45+0.20 | 9,40 kg | 500 | Add to request list |

| SK-B12 | 096560 | Ø 12.40+0.58 | Ø 32.30-0.62 | 2.80±0.06 | 4.30+0.20 | 15,40 kg | 250 | Add to request list |

Technical changes reserved

The securing effect of the SK-B on slotted holes is verified using a wide range of test methods. The hole clearance in the transverse direction corresponds to normal holes (DIN EN 20273; tolerance class H 13, medium). Furthermore, slotted hole edges are always deburred. For your own applications, it is recommended that you carry out your own tests with specialised personnel.